TORONTO, CANADA - Tsodilo Resources Limited (TSX-V:TSD) ("Tsodilo" or the "Company") is pleased to provide an update of its Botswana Iron Ore exploration (evaluation) activities, as well as its general Botswana exploration programs July through October 2013 (the "period").

Summary

- Thirty (30) Iron Ore exploration (resource definition) holes were drilled during the period totaling 4,968.75 meters.

- Twenty-three (23) of these holes intersected 1,795.05 meters of Iron mineralization.

- 1062 XRF assay analysis were received for 18 holes in the period, intersecting 1134.38 meters of magnetite Iron mineralization at an average grade of; 36.61% Fe; 36.18% SiO2; 4.87 % Al2O3; 0.277% P; and 1.91% LOI.

- Density results for 651 magnetite Iron mineralization measurements indicate and average mineralization density of 3.3 g/cm3.

- Drilling results indicate two distinct mineralized units within the Xaudum Fe Formation; a Magnetite Banded Iron Formation (BIF) and a Magnetite Schist.

- Copper (Cu) exploration drilling conducted by the Company's joint venture partner First Quantum Minerals (FQM) started during the period, including both deep diamond core drilling (DD) and reverse circulation (RC) drilling.

- A major airborne survey collecting electromagnetic (AEM), magnetic, and radiometric data (for radioactive minerals exploration) was initiated by FQM and completed during the period using Spectrem Air Ltd. ("Spectrem"), the data is currently being analyzed.

- The high resolution ground magnetic survey continued during the period, covering 983 line kilometers (over 57 km2).

Xaudum Iron Ore Project

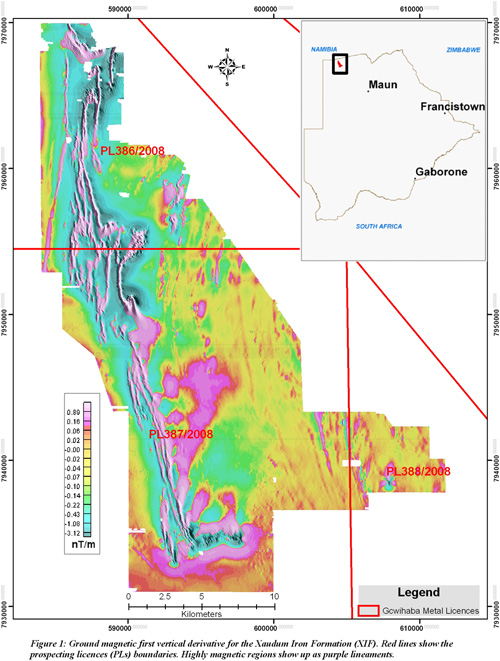

The Company's major exploration focus during the period was the continuation of the resource definition drilling on the Xaudum Iron Formation ("XIF") magnetite iron ore target. The XIF takes its name from the Xaudum River that runs through the northern portion of the Ngamiland region in the North-West District of Botswana. The XIF generally does not outcrop (one small outcropping area in the old quarry area in Shakawe) and is considered a buried prospect. The XIF is buried below the "Kalahari cover" (Kalahari Group sediments dominantly made up of sand and calcrete) and has been delineated for exploration drilling using detailed ground magnetic surveys conducted by the Company over the area. The ground magnetic survey comprises 18,000 line kilometers ("km") on lines 50 meters apart and covers 1600km². The XIF is located within two base metal prospecting licenses (PL386/2008 and PL387/2008) and stretches over 35km (see Figure 1).

Drilling to date has confirmed that the XIF is comprised of two units:

- Magnetite Banded Iron Formation (BIF) unit, which can be weathered near surface (just below the Kalahari cover).

- Magnetite Schist unit, which can also be weathered near surface.

These units are significantly magnetic, although the Magnetite BIF is more magnetic and can be considered a high grade magnetite unit, whereas the Magnetite Schist represents a less magnetic but potentially more widespread lower grade target unit.

Both units are believed to represents metamorphosed chemical sediments that have been highly deformed, resulting in strong and well developed banding in the Magnetic BIF and a strong foliation within the Magnetic Schist. The magnetite mineralization is more disseminated within the Magnetite Schist and not as obviously partitioned into bands like the Magnetite BIF.

It is unclear whether these Magnetite BIF and Magnetite Schist units are comprised of single or multiple stratigraphic units. The intense deformation, folding and potential thrusting that these units have undergone, means defining stratigraphy and true thicknesses is difficult to determine, especially at this relatively early stage of resource drilling. The course grain-size nature within the Magnetite Schist suggests that there should be good magnetic separation potential within this unit similar to that already shown in preliminary Davis Tube Recovery (DTR) of the Magnetite BIF (with Fe grades of 69.5 to 71.8% and significant reduction of deleterious elements SiO

2, Al

2O

3 and P to acceptable levels). Additional detailed DTR work is currently being conducted on a variety of grade of composites by ALS Minerals Division at their Iron Ore Technical Centre (Wangara, Perth, Western Australia), including Magnetite Schist material.

These two XIF units occur within the Grand Conglomerate (which is referred to as a diamictite schist) horizon. These Grand Conglomerate diamictites are a glacial origin marker horizon within the Neoproterozoic in the region. The Magnetite Schist is a magnetic (high in magnetite) version of the main diamictite schist (normally non-magnetic) and therefore the Magnetite Schist is also referred to as a magnetite diamictite or magnetic diamictite.

The XIF has been identified as a Rapitan style BIF of Neoproterozoic age. Neoproterozoic BIF formations have been proposed to have formed during or in the immediate aftermath of the so called Neoproterozoic "Snowball Earth" state at that time (considered to be around 0.6-0.8 Ga in age). Other examples of this Neoproterozoic BIF include the Rapitan Group in northwest Canada (18.6 billion tonnes at 47% Fe); the Yudnamutara Subgroup, Braemar Iron Formation, Australia (1.4 billion tonnes at 15.5% Fe); the Chuos Formation (Namibia); and the Jacadigo Group (Brazil, Urucum district) ~30+ Billion tonnes at ~50% Fe).

Drilling

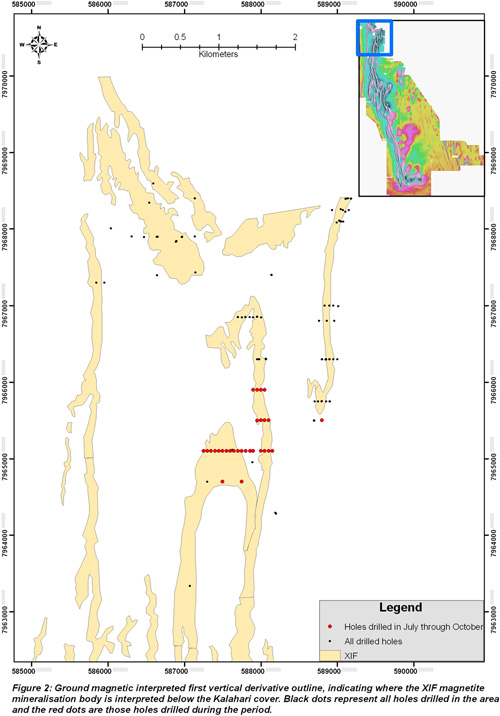

The drilling program is focused on the northern part of the XIF close to the Namibian border (Figure 2). The companies' two diamond drill rigs continue to focus on evaluation resource drilling to arrive at an inferred resource (Quarter 2, 2014). Due to the strong north-south elongation of the Iron Formation along strike, drillholes are currently being located at 50 meter intervals along the east-west orientated section (fence) lines which are approximately 400 meters apart along strike.

These section lines require between 6 to 20 drillholes to define the complexities of the formation and holes are drilled either vertical, or inclined to the east or west dependent on our knowledge of the dip of the formation. These holes are surveyed using the Reflex non-magnetic Gyroscope deviation survey tool. This tool accurately measures the direction and dip deviation of these holes within the ground, and the deviation survey results are captured in our dedicated drillhole database. The core is also orientated for accurate structural and geotechnical measurement readings (see below) using the Reflex ACT II core orientation device.

Thirty (30) Iron Ore exploration (resource definition) holes were drilled during the period totaling 4,968.75 meters. Twenty-three (23) of these holes intersected 1,795.05 meters of XIF mineralization as either Magnetite BIF or Magnetite Schist units. The 7 holes that did not intersect Iron mineralization help define the limits of the mineralization; increase the knowledge of the regional geology and geological structure; and assist in refining future drilling targets. Geotechnical logging of these rocks contributes to the knowledge of the geotechnical parameters of the waste rock surrounding the mineralization.

Iron Ore Post Drilling Procedures

The orientated core is logged geotechnically and structurally on the drill site by an experienced geologist, geotechnical measurements are taken on a run by run basis for rock quality designation (RQD), material strength and fracture count. Further to this, structural measurements of alpha (α) and beta (β) angles from the orientated core are taken of the bedding, foliation, fractures, joints, and other discontinuities such as veins and faults. This information is captured digitally in our drillhole database for later use in geological software and analysis, as well as for plotting on down-hole traces on geological cross sections to aid in interpretation.

Magnetic susceptibility readings are taken of the core every 20-50 cm providing instant first-order understanding of the mineralogy of the Iron bearing rocks being drilled. This information is captured in the company's drillhole database

The entirety of the core is then logged in detail by experienced geologists using a material type percentage logging system. From this a first pass down-hole interpretation is made to assign geological and ore Geodomains; where the Magnetite BIF is referred to as MBA for Magnetite Banded, the Magnetite Schist is referred to as DIM for Magnetic Diamictite, and non-magnetic diamictite (waste) is referred to as DIA for Diamictite (logging and Geodomains are captured in our drill hole database).

These Geodomains are then used to pick ore intervals from the core to send for chemical X-Ray Florescence (XRF) assay, plus possible mineralogical or DTR test work. The core is then cut using an Almonte Pty. automated core feed saw.

Iron Ore Sampling and QAQC (Quality Control and Quality Assurance)

The split mineralized core (half core) is sampled at 2 meter intervals and extends 20 meters on either side of the ore zones to account for variation along the ore-waste contact zone, plus to help with waste rock characterization, and define the relationship the ore has with the surrounding rock.

These 2 meter samples are measured for density using the Archimedean method of weighing dry and then weighing submerged in water. The density measurements are supplemented with QAQC check samples to ensure precision and repeatability of the density measurements. These QAQC check samples include Standards and Test Weights (5 and 10 kg) to ensure accuracy of the scale (AND GF-10K scale, precise to 0.1g) and density measurement. The accuracy of the scale has been shown to be within less than 15g. The precision of the technique has been shown to be ~0.05 g/cm

3, which is the 2 stand deviations of the mean (2 s.d.) of the density standard measurements, showing that the precision of the technique is good. Density duplicates and repeats are included to check the repeatability of the technique and sampling method. The duplicates (quarter core) and repeat measurements have been shown to have excellent repeatability with correlation coefficient (R) values of 0.988 and 0.996 respectively. The density QAQC results show that the applied density methodology is fit for purpose.

These 2 meter samples from the split cores are then bagged and labeled, and consigned for crushing, pulverizing (pulp creation) and XRF chemical assay to the ALS Minerals Division Geochemistry laboratory (lab) in Johannesburg, South Africa. Inserted into this sample stream and also sent to the lab for XRF assay analysis are our in house QAQC check samples. These include 3 Geostats Pty. Geostats Iron Ore Pulp (GIOP) standards that are generally matrix matched to and cover the chemical range of the XIF magnetite iron mineralization samples. These are inserted 1 in every 20 samples into the sample stream, cycling through the 3 standards. These standards check the accuracy of the XRF assay analysis. Further to this Blanks are inserted comprised of a clean white river sand (~ 99% SiO

2), which was collected from a river channel near Shakawe. These Blanks are inserted into the sample stream 1 in every 20 samples and are used to check for sample to sample contamination during sample preparation at the lab. Quarter core duplicates are also taken at an interval of 1 in every 20 samples, and sent to the lab for analysis, these check our sampling process and technique for repeatability and precision.

All returned XRF assay results are checked that they pass QAQC before they are uploaded into the Company's drillhole database. This means that the GOIP standards are checked against the control limits and all have passed so far. The blank sand is checked for contamination and none has been identified so far. The duplicates are plotted against original for precision (how close they fall to the 1:1 line) and the correlation coefficient (R) values of the duplicates is 0.998 for Fe analysis, and shows no perceivable bias (all data fall close to the 1:1 line). All assays batches that included QAQC samples to date have satisfactorily passed the QAQC checks and have been uploaded into the database.

Results

XRF assays for eighteen (18) different holes totaling 1062 samples were received during the period consisting of 1,135.38 meters of intersected mineralization, 925.58 meters of Magnetite BIF and 209.8 meters of Magnetite Schist. The interval weighted average grade of the Magnetite BIF, Magnetite Schist, and average of both units, for these holes is shown in Table 1 below. The hole by hole breakdown is shown in Table 2. The "Total Meters Intersected" column in Table 1 is the cumulative meters intersected for the mineralized unit in these holes. Note that 4 holes intersected both units. The intervals used in creating these weighted averages are the same as those shown in Table 2 below, as per Table 2 no internal waste intervals were removed. LOI refers to total LOI at 1000oC. The density values are in g/cm

3, and taken from a larger data set than the assay results (see Table 3 below).

Table 1. XRF assay results for the period

| Number of Holes |

Total Meters Intersected |

Mineralized Unit |

Fe |

SiO2 |

Al2O3 |

P |

LOI |

Average Density |

| 16 |

925.58 |

Magnetite BIF (MBA) |

36.61 |

32.59 |

3.67 |

0.299 |

1.98 |

3.5 |

| 8 |

209.80 |

Magnetic Schist (DIM) |

17.33 |

52.00 |

10.16 |

0.177 |

1.57 |

3.0 |

| 18 |

1134.38 |

Average of both Units |

33.05 |

36.18 |

4.87 |

0.277 |

1.91 |

3.3 |

Table 2 sets forth the interval weighted averages for each of the 18 drillholes for which XRF assay data were received during the period. No internal waste intervals were removed and the averages are calculated as weighted averages to the assay sample interval length.

Table 2. XRF assay data for the interval weighted average for 18 drillholes

| Hole ID |

From |

To |

Interval |

Mineralized Unit (Geodomain) |

Fe |

SiO2 |

Al2O3 |

P |

LOI |

Mn |

S |

MgO |

CaO |

| 1821B115E67U |

82.23 |

185 |

102.77 |

Magnetite BIF (MBA) |

38.69 |

32.19 |

3.21 |

0.329 |

1.84 |

0.711 |

0.105 |

1.90 |

3.57 |

| 1821B115V67U2 |

187 |

227.1 |

40.1 |

Magnetite BIF (MBA) |

41.67 |

28.77 |

2.17 |

0.322 |

1.76 |

0.714 |

0.116 |

1.63 |

3.72 |

| 1821B115W67T |

18 |

31.9 |

13.9 |

Magnetite BIF (MBA) |

35.04 |

38.01 |

1.09 |

0.205 |

4.85 |

0.682 |

0.026 |

0.78 |

3.15 |

| 1821B115W67T |

295.1 |

297.2 |

2.1 |

Magnetite BIF (MBA) |

32.43 |

38.87 |

5.75 |

0.261 |

-0.31 |

1.425 |

0.395 |

1.75 |

3.31 |

| 1821B116E78V |

12 |

34 |

22 |

Magnetite BIF (MBA) |

34.58 |

36.80 |

1.97 |

0.210 |

4.90 |

0.501 |

0.007 |

0.86 |

4.12 |

| 1821B116E78V |

50 |

62 |

12 |

Magnetite BIF (MBA) |

35.41 |

35.82 |

5.07 |

0.364 |

0.98 |

0.700 |

0.042 |

1.87 |

2.99 |

| 1821B116E78V |

86 |

152 |

66 |

Magnetite BIF (MBA) |

36.19 |

34.41 |

3.73 |

0.305 |

1.40 |

0.784 |

0.037 |

1.87 |

3.49 |

| 1821B116E78V |

152 |

176 |

24 |

Magnetite Schist (DIM) |

16.28 |

46.84 |

10.19 |

0.202 |

3.75 |

2.207 |

0.030 |

3.62 |

3.29 |

| 1821B116E78W |

38 |

62 |

24 |

Magnetite BIF (MBA) |

35.00 |

34.23 |

3.63 |

0.370 |

3.67 |

0.692 |

0.063 |

1.23 |

4.06 |

| 1821B116E78W |

70 |

146 |

76 |

Magnetite BIF (MBA) |

39.48 |

29.15 |

3.55 |

0.317 |

2.10 |

0.641 |

0.044 |

1.98 |

4.23 |

| 1821B116E78X |

88 |

154 |

66 |

Magnetite BIF (MBA) |

34.92 |

34.40 |

4.88 |

0.287 |

1.44 |

0.931 |

0.050 |

1.95 |

3.87 |

| 1821B116W78T |

90 |

144 |

54 |

Magnetite BIF (MBA) |

37.00 |

31.89 |

4.10 |

0.334 |

1.76 |

1.175 |

0.038 |

1.91 |

4.05 |

| 1821B116W78T |

192 |

224 |

32 |

Magnetite BIF (MBA) |

37.01 |

32.93 |

4.21 |

0.299 |

1.37 |

0.878 |

0.145 |

1.85 |

3.59 |

| 1821B116W78T |

240 |

258 |

18 |

Magnetite Schist (DIM) |

19.27 |

45.44 |

9.73 |

0.223 |

1.68 |

2.086 |

0.072 |

3.39 |

2.55 |

| 1821B116W78T |

270 |

353.4 |

83.4 |

Magnetite BIF (MBA) |

36.25 |

33.04 |

4.04 |

0.283 |

1.70 |

0.889 |

0.297 |

2.32 |

3.80 |

| 1821B117E75AM |

52 |

114 |

62 |

Magnetite Schist (DIM) |

16.06 |

55.63 |

10.46 |

0.158 |

0.93 |

0.178 |

0.014 |

1.50 |

1.80 |

| 1821B118E83X |

134 |

144 |

10 |

Magnetite Schist (DIM) |

17.33 |

46.86 |

10.08 |

0.210 |

2.74 |

1.858 |

0.012 |

3.02 |

2.52 |

| 1821B120E83AL |

60 |

104 |

44 |

Magnetite Schist (DIM) |

16.15 |

54.54 |

11.23 |

0.160 |

1.16 |

0.109 |

0.022 |

1.63 |

1.81 |

| 1821B120E83AL |

104 |

114 |

10 |

Magnetite BIF (MBA) |

31.93 |

39.12 |

4.27 |

0.212 |

1.82 |

1.123 |

0.050 |

1.39 |

3.46 |

| 1821B120E83AM |

126 |

154 |

28 |

Magnetite Schist (DIM) |

19.91 |

51.28 |

9.03 |

0.173 |

1.03 |

0.601 |

0.033 |

1.47 |

2.29 |

| 1821B83E |

57.5 |

61.2 |

3.7 |

Magnetite Schist (DIM) |

14.29 |

56.84 |

10.79 |

0.154 |

1.98 |

0.143 |

0.014 |

1.77 |

2.48 |

| 1821B83E |

61.2 |

66.6 |

5.4 |

Magnetite BIF (MBA) |

36.18 |

30.89 |

2.86 |

0.282 |

4.16 |

1.514 |

0.004 |

1.08 |

5.04 |

| 1821B83E67AM |

65.9 |

86 |

20.1 |

Magnetite Schist (DIM) |

20.31 |

49.91 |

8.73 |

0.195 |

1.81 |

0.442 |

0.012 |

1.52 |

2.59 |

| 1821B90E56AL |

32.4 |

72.4 |

40 |

Magnetite BIF (MBA) |

36.00 |

35.08 |

2.22 |

0.241 |

3.77 |

1.342 |

0.003 |

0.89 |

2.94 |

| 1821B90E56AR |

101.9 |

143.7 |

41.8 |

Magnetite BIF |

38.79 |

31.50 |

2.40 |

0.272 |

2.17 |

1.314 |

0.040 |

1.77 |

3.43 |

| 1821B90E56AS2 |

66 |

110.5 |

44.5 |

Magnetite BIF (MBA) |

39.38 |

33.42 |

2.16 |

0.298 |

1.52 |

0.909 |

0.061 |

1.68 |

2.13 |

| L9600_10E31R |

3.4 |

50.4 |

47 |

Magnetite BIF (MBA) |

40.77 |

31.57 |

2.01 |

0.308 |

2.74 |

0.430 |

0.018 |

0.61 |

2.55 |

| L9600_10W |

5.79 |

148.4 |

142.61 |

Magnetite BIF (MBA) |

34.76 |

32.25 |

3.60 |

0.252 |

3.60 |

0.863 |

0.069 |

2.04 |

3.94 |

Table 3 shows the average density for both mineralized units (Magnetite BIF Geodomain MBA, and Magnetite Schist Geodomain DIM). All density figures are in g/cm

3; 2 s.d. = two standard deviations of the mean (average); Min = the minimum density value measured in the mineralized Geodomain; Max = the maximum density value measured in the mineralized Geodomain; Count = the number of measurements taken and on which the statistics are based.

Table 3. Average densities for mineralized units

| Mineralized Unit |

Average |

2 s.d. |

Min |

Max |

Count |

| Magnetic BIF (MBA) |

3.5 |

0.69 |

2.76 |

4.83 |

397 |

| Magnetic Schist (DIM) |

3.0 |

0.32 |

2.43 |

3.47 |

254 |

| Average of both mineralized units |

3.3 |

0.78 |

2.43 |

4.83 |

651 |

As mentioned above, the density measurements are made on the same 2 meter samples that are sent away for assay, this means that there are no gaps in the density measurements record for the mineralized units. The interval chosen to take the density averages are based on the Geodomain designation, and therefore include all "short interval" internal waste and lower grade material that is included in the Geodomain interval. Therefore there is no bias towards high grade samples in these averages. This also accounts for the broad range (Min and Max) of the densities within these Geodomains and their relatively large standard deviations. Therefore, it is considered that these averages represent the best approximation to date of the likely bulk in-situ density of these mineralized units at a mineable domain scale. Density measurements will continue to be taken and these averages will improve over time along with our understanding of the geology of the project.

First Quantum Minerals

Copper (Cu) exploration drilling conducted by the Company's joint venture partner First Quantum Minerals (FQM) started during the period. Two phases of drilling were initiated. Firstly a line of deep holes across the strike of the general geology have been planned using diamond core drilling (DD) to develop a geological model at greater depths. Two holes were completed in the 3rd Quarter to an accumulative depth of 851m. Secondly, FQM has started a Reverse Circulation drilling (RC) program on a 2 km grid over the Company's PL386/2008, PL387/2008 and PL388/2008 license areas, to sample the Kalahari Group sediments but specifically to geochemically sample the interface between the weathered bedrock and the overlying Kalahari cover sediments.

Geophysics

A high resolution ground magnetic survey using the company's own Cesium Vapor and Proton Precession magnetometers continued during the period, covering 983 line kilometers over 57 km2. The general strike of the iron formation is north-south; therefore lines were designed to run perpendicular to this body in the east-west direction. A line spacing of 50 meters and station spacing equivalent to one reading every 5 seconds (~ 5-6 meters) was employed to better cover some of the thinner magnetite units, averaging 100 meters in width. All data corrections which include despiking, destriping, diurnal, and tie-line leveling were performed using Geosoft software. Minimum curvature and bi-directional gridding, in conjunction with various filters and transforms, i.e. derivatives, continuations, reduction to pole, analytical signal etc. were performed to produce maps and profiles for visual and modeling purposes, see interpreted XIF from vertical derivatives in Figure 2.

Magnetic data, drillhole Geodomains, susceptibility and assay data were integrated in Geosoft Target software to produce geologic sections. These were used to plan future holes and importantly for cross sectional interpretations as a precursor to geological modelling

A major airborne electromagnetic survey (AEM), covering licenses PL386/2008 to PL395/2008 and PL093/2012 to PL097/2012, was initiated by FQM. Spectrem Air Ltd. ("Spectrem"), a wholly owned subsidiary of Anglo Operations Ltd, was contracted to conduct the survey. Spectrem using the SPECTRUM2000 fixed wing system, a highly successful proprietary airborne electromagnetic technique used to detect conductive horizons. At the same time airborne magnetic and radiometric data was collected by the same system. This regional electromagnetic survey over the broader Gcwihaba area was flown on flight lines 1000m apart maintaining an elevation of some 70 meters. A more detailed survey over the XIF was flown at 200 meter line spacing at the same elevation. Towards the end of the period the detailed survey was completed and 2,538 line kilometers were flown. The regional survey was completed in October and for both surveys a total of 16,932 line kilometers was flown. The data is currently being analyzed.

Diamond Exploration

All 36 soil samples collected over Prospecting License PL95/2012, which is situated south west of the Jwaneng Diamond mine, were re-screened, concentrated by jigging and further concentrated by heavy liquid separation. These samples produced four chromites and one garnet. The grains will be prepared for micro-probe analysis to assess its priority rating.

Kimberlite targets TOD 17, 29 and 30 (PL 46 and 47/2008) are scheduled to be drilled in the 4th Quarter. The Company is still waiting for the Ministry of Minerals, Energy and Water Resources (MMEWR) to approve the renewal applications for PL 64/2005 before further work is performed.

Radioactive Minerals Exploration

As mentioned above radiometric data was collected by Spectrem Air Ltd. ("Spectrem") using their SPECTRUM2000 fixed wing system over a large area at 1000 meter line spacing, the wide area survey, and at 200 meter line spacing, the infill survey, over the Xaudum Iron Formation area at an elevation of 70 meters (initiated by our joint venture partners FQM). The flying of the infill survey was completed and the wide area survey, covering a large part of the Company's prospecting licenses, was completed in October having flown 16,932 line kilometers.

Future work

Drilling of the Xaudum Iron Ore Project will continue to move south along the XIF at the current 400 x 50 meter drillhole spacing to obtain sufficient data for commencement of an initial NI 43-101 mineral resource estimate report.

FQM is planning to fly an airborne gravity survey of the main part of the license blocks and coinciding with the Spectrem dataset during the next quarter. Their diamond and RC drilling program will also continue.

Health, Safety, Community and Environment

Safety incidents were low during the period. There were two minor incidents during the period resulting in the loss of two days for the one injury and zero days for the second.

There were no environmental incidents during the period.

Four well attended community meetings were held during the period in the villages of Mohembo, Nxamasere Sepopa and Shakawe villages. These meetings are one of the means employed by the company to inform and update the local communities and government officials of the Company's exploration activities.

About Tsodilo Resources Limited: Tsodilo Resources Limited is an international diamond and metals exploration company engaged in the search for economic diamond and metal deposits at its Newdico (Pty) Limited ("Newdico") and Gcwihaba Resources (Pty) Limited ("Gcwihaba") projects in northwest Botswana. The Company has a 98% stake in Newdico (895 km2 under Precious Stone - diamond licenses). The Gcwihaba project area: 2,404 km2 under Precious Stone - diamond licenses; 11,158 km2 Metal (base, precious, platinum group, and rare earth) licenses; and, 6,925 km2 under Radioactive Minerals licenses is 100% held by the Company. Tsodilo manages the exploration of both the Newdico and Gcwihaba license areas. Overall supervision of the Company's exploration program is the responsibility of Dr. Mike de Wit, President and COO of the Company and a "qualified person" as such term is defined in National Instrument 43-101. Dr. de Wit has reviewed the information contained herein and approved the contents of this Press Release. Further to this, the supervision of the Xaudum Iron Ore project is the responsibility of Dr. Alistair Jeffcoate, Chief Geologist and Project Manager for the Company and a "qualified person" as such term is defined in National Instrument 43-101. Dr. Jeffcoate has also reviewed the information contained herein and approved the contents of this press release.

The Company has offices in Toronto, Canada and Gaborone and Maun, Botswana. Please visit the Company's website, www.TsodiloResources.com, for additional information and background on our projects.

National Instrument 43-101 - Standards of Disclosure for Mineral Projects, Form 43-101F1 and Companion Policy 43-101CP requires that the following disclosure be made: All references contained herein with respect to the potential quantity and grade derived by any method is at this stage of development conceptual in nature. At the present time, there has been insufficient exploration to define a mineral resource and it is uncertain if further exploration will result in the target being delineated as a mineral resource.

This press release contains forward-looking statements. All statements, other than statements of historical fact, that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future (including, without limitation, statements relating to the development of the Company's projects) are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Forward-looking statements are subject to a number of risks and uncertainties that may cause the actual results of the Company to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company. Factors that could cause actual results or events to differ materially from current expectations include, among other things, changes in equity markets, political developments in Botswana and surrounding countries, changes to regulations affecting the Company's activities, uncertainties relating to the availability and costs of financing needed in the future, the uncertainties involved in interpreting exploration results and the other risks involved in the mineral exploration business. Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward-looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.

The TSX Venture Exchange has not reviewed and does not accept responsibility for the adequacy or accuracy of this news release. This news release may contain assumptions, estimates, and other forward-looking statements regarding future events. Such forward-looking statements involve inherent risks and uncertainties and are subject to factors, many of which are beyond the Company's control, which may cause actual results or performance to differ materially from those currently anticipated in such statements.

FOR FURTHER INFORMATION PLEASE CONTACT:

James M. Bruchs

Chairman and Chief Executive Officer

JBruchs@TsodiloResources.com

Dr. Mike de Wit

President and Chief Operating Officer

MdeWit@TsodiloResources.com

Head Office

Telephone +1 416 572 2033

Facsimile + 1 416 987 4369

Website

http://www.TsodiloResources.com